Machinery

- Complete Chocolate Business (Everything Included): $2.2 Million

- Industrial Building: $950K

- Machinery: $380K

- Know-how, implemented ERP system, over 120 chocolate formulas, FSSC 22000, and USDA organic certifications: $880K

We are open to offers.

1- Cleaning And Sorting Of Cacao Beans

Cleans and classifies cocoa beans by size, removing impurities such as metals, stones, wood, and sticks, ensuring a higher quality product for chocolate production. Main parts are made of stainless steel.

Cleaner and Sorter with 3 outputs

- Dimensions(mm): 4970X1900X3100

- Weight(Kg): 1200

- Capacity (Kg/h): 750

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 7.74(Kw)

2.- Cocoa Bean Roasting

Electric equipment that ensures consistent roasting, enhancing the flavors and aromas of the cocoa. It includes an integrated cooling tray for rapid temperature reduction, maintaining the optimal quality of the beans.

Roaster with cooling tray

- Dimensions(mm): 1938x130x870

- Weight(Kg): 650

- Capacity (Kg/h): 90

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 18(Kw)

3.- Cocoa bean winnowing

Designed to precisely break cocoa beans, facilitating the separation of nibs from the husk.

Cocoa Bean Winnower

- Dimensions(mm): 1780X1990X890

- Weight(Kg): 400

- Capacity (Kg/h): 100

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 3Kw

4.- Shell removal and nib extraction

Specialized machine for efficiently removing the shell from cocoa beans. This equipment is crucial for preparing cocoa nibs, ensuring a clean product ready for milling. Parts in contact with the nibs are made of stainless steel.

Cleaning and Unhusked

- Dimensions(mm): 4970X1900X3100

- Weight(Kg): 1200

- Capacity (Kg/h): 90

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Fases / 9.5Kw

4.1 - Complementary equipment

Designed to precisely break cocoa beans, facilitating the separation of nibs from the husk.

Suction conveyors

- 1 from the cocoa cooler to the cocoa cracker.

- 1 from nib carts to the cocoa liquor mill.

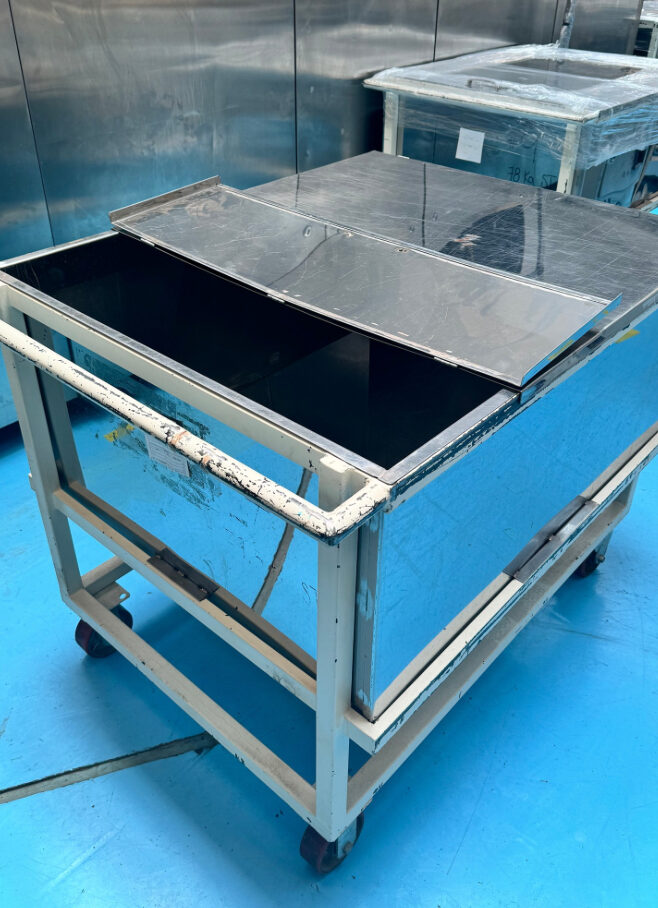

Stainless steel nib storage carts

Storage of 350 kg of nibs each.

5.- Cocoa BEANS GRINDING

Designed to grind roasted cocoa nibs using stones and produce cocoa liquor with an approximate fineness of 120 microns. Ensures a fine and uniform texture in the final product. It has a water cooling system.

CACAO BEANS GRINDER

- Dimensions(mm): 1530x1620x560

- Weight(Kg): 700

- Capacity (Kg/h): 150

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 22Kw

6.- Conching of ingredients (500 kg)

Capable of conching up to 500 kg of chocolate, enhancing its texture and developing depth in aromas and flavors. Large-scale refining ensures chocolate with 22-28 microns fineness. Equipped with a PLC.

500 kg Conche

- Dimensions(mm): 2800x1500x1700

- Weight(Kg): 2000

- Capacity (Kg/h): 21

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 32.1 Kw

6.1 - Conching of ingredients (1000 kg)

Capable of conching up to 1000 kg of chocolate, enhancing its texture and developing depth in aromas and flavors. Large-scale refining ensures chocolate with 22-28 microns fineness.

1000 kg Conche

- Dimensions(mm): 1320x1640x2570

- Weight(Kg): 4000

- Capacity (Kg/h): 41.6

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 32.1 Kw

7.- Chocolate storage (500 kg)

Designed to keep chocolate in optimal conditions, these tanks feature agitation systems and temperature control to ensure uniform consistency and prevent solidification.

500 kg tanks / temperature-controlled

- Dimensions(mm): *Φ1100×1500 (500kg)

- Weight(Kg): 250

- Capacity (Kg/h): 500

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 1.5 Kw

8.- Chocolate storage (1000 kg)

Designed to keep chocolate in optimal conditions, this tank features agitation systems and temperature control to ensure uniform consistency and prevent solidification.

1000 kg tank / temperature-controlled

- Dimensions(mm): Φ1220×2145 (1000Kg)

- Weight(Kg): 480

- Capacity (Kg/h): 1000

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 2.2 Kw

9.- Chocolate tempering

It incorporates a coil with four temperature settings, facilitating precise control for optimal cocoa butter crystallization, resulting in a shiny finish and uniform texture in the chocolate. It includes a PLC (Programmable Logic Controller).

Tempering machine

- Dimensions(mm): 1100x970x1720

- Weight(Kg): 780

- Capacity (Kg/h): 300

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 3 Kw

9.1 Complementary equipment

Viscometer

It measures the viscosity of a fluid using a submerged rotor that spins at a controlled speed; the resistance to rotation, measured by the torque required to maintain the rotor’s speed, indicates the fluid’s viscosity.

TRICOR 225 Temperimeter

The 225 Temperimeter is a compact and portable device that quickly and accurately measures the tempering of chocolate, providing printed results and allowing adjustments in tempering machines (TRICOR Systems, Inc.).

10.- Injection, cooling, and demolding

This PLC-controlled machine combines precision in injecting chocolate into molds with an integrated cooling tunnel for rapid and even cooling. It accommodates 400 molds and ensures optimal solidification and perfect demolding of the chocolate. Additionally, it features “One Shot” technology, allowing for the injection of filled chocolate in a single pass..

Chocolate molding machine

- Dimensions(mm): 17500x970x1520

- Weight(Kg): 5500

- Capacity (Kg/h): 90-150

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 40.5Kw

- Type: Filled bonbons, bars, discs, blocks. (Molds—various shapes)

11.- Preparation of additives

Equipped with blades, which break and classify the processed additive by size.

Nuts/nibs cutter

- Dimensions(mm): 2680x1260x98

- Weight(Kg): 500

- Capacity (Kg/h): 30

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 2.25 Kw

12.- Metal detection for all chocolate

Equipped with high-sensitivity technology to identify and remove metal contaminants in food products. This device is crucial for ensuring safety and quality on the production line.

Food Metal Detector

- Dimensions(mm): 1520X830X1000

- Weight(Kg): 250

- Capacity (Kg/h): N/A

- Condition-Origin: Excellent - China

- Years of use: 5

- Input/Power: 220V, 60Hz, 3 Phases / 0.1 Kw

13.- Bar packaging machine

Designed to efficiently wrap chocolate bars, this machine automates the packaging process, ensuring airtight sealing and an attractive product presentation. It is ideal for high-production operations.

Bar Wrapper

- Dimensions(mm): 3370x670x1410

- Weight(Kg): 800

- Capacity (Kg/h): 60-80

- Condition-Origin: Excellent - China

- Years of use: 2

- Input/Power: 220V, 60Hz, 3 Phases / 2.4 Kw

14.1 Complementary packaging equipment

5 Continuous sealer SF150/W-110V-60HZ

It allows for batch labeling and heat sealing of doypacks, handling between 200-300 per hour.

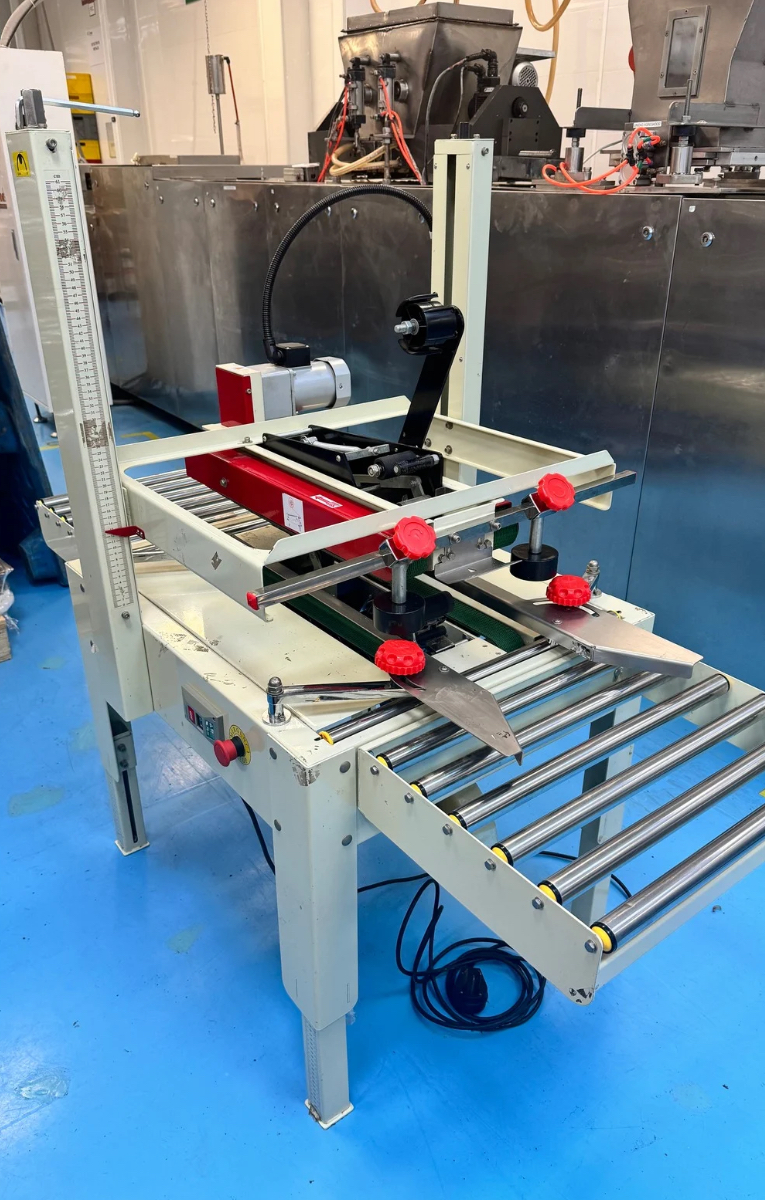

Case sealer

Case sealer with adhesive tape for the top and inner sides, handling 200-300 boxes per hour.

15.1 Other production equipment

Electric forklift

Powered by batteries

- Voltage: 48V DC

- Capacity: 1.5 tons

- Energy: 400Ah

- Dimensions(mm): 3000x1000x2200

Dehumidifier

t is essential for maintaining low humidity levels, which is crucial for preserving the quality and stability of chocolate.

- Capacity: 138L / area of 120 to 160 m³

17. Laboratory design and development equipment

Bean roaster

1.3 kg capacity

8 lb conching machines

Rev 2 Tempering Machine

Refrigerator

Coating machine

Kitchen

18.1 Quality control equipment

Precision scale - up to 100 grams

Colony counter

Sterilizer

Incubator

18.1 Quality control equipment

Swab incubator

Grain moisture meter

Refrigerator

24L Autoclave

Acquire the complete business, including the industrial plant, machinery, tax credits in Ecuador, proprietary know-how, FSSC 22000 & USDA certification, and an established client portfolio.

A spacious 1,000 m² plant, perfectly designed for efficient chocolate production, located in an industrial area in Quito, Ecuador